|

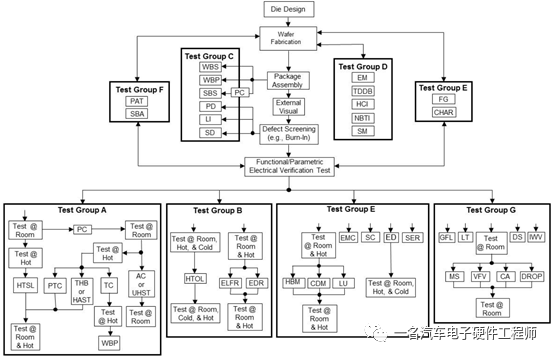

TEST GROUP A – ACCELERATED ENVIRONMENT STRESS TESTSAOwednc |

|

#AOwednc |

STRESSAOwednc |

ABVAOwednc |

SAMPLE SIZE / LOTAOwednc |

|

A1AOwednc |

PreconditioningAOwednc |

PCAOwednc |

77AOwednc |

|

A2AOwednc |

Temperature Humidity-Bias or Biased HASTAOwednc |

THB or HASTAOwednc |

77AOwednc |

|

A3AOwednc |

Autoclave or Unbiased HAST or Temperature Humidity (without Bias)AOwednc |

AC or UHST or THAOwednc |

77AOwednc |

|

A4AOwednc |

Temperature CyclingAOwednc |

TCAOwednc |

77AOwednc |

|

A5AOwednc |

Power Temperature CyclingAOwednc |

PTCAOwednc |

45AOwednc |

|

A6AOwednc |

High Temperature Storage LifeAOwednc |

HTSLAOwednc |

45AOwednc |

|

TEST GROUP B – ACCELERATED LIFETAOwednc |

|

#AOwednc |

STRESSAOwednc |

ABVAOwednc |

SAMPLE SIZE / LOTAOwednc |

|

B1AOwednc |

High Temperature Operating LifeAOwednc |

HTOLAOwednc |

77AOwednc |

|

B2AOwednc |

Early Life Failure RateAOwednc |

ELFRAOwednc |

800AOwednc |

|

B3AOwednc |

NVM Endurance, Data Retention, and Operational LifeAOwednc |

EDRAOwednc |

77AOwednc |

|

TEST GROUP C – PACKAGE ASSEMBLY INTEGRITY TESTSAOwednc |

|

#AOwednc |

STRESSAOwednc |

ABVAOwednc |

SAMPLE SIZE / LOTAOwednc |

|

C1AOwednc |

Wire Bond ShearAOwednc |

WBSAOwednc |

30 bonds from a minimum of 5 devicesAOwednc |

|

C2AOwednc |

Wire Bond PullAOwednc |

WBPAOwednc |

|

C3AOwednc |

SolderabilityAOwednc |

SDAOwednc |

15AOwednc |

|

C4AOwednc |

Physical DimensionsAOwednc |

PDAOwednc |

10AOwednc |

|

C5AOwednc |

Solder Ball ShearAOwednc |

SBSAOwednc |

5 balls from a min. of 10 devicesAOwednc |

|

C6AOwednc |

Lead IntegrityAOwednc |

LIAOwednc |

from each 10 leadsAOwednc

of 5 partsAOwednc |

|

TEST GROUP D – DIE FABRICATION RELIABILITY TESTSAOwednc |

|

#AOwednc |

STRESSAOwednc |

ABVAOwednc |

SAMPLE SIZE / LOTAOwednc |

|

D1AOwednc |

ElectromigrationAOwednc |

EMAOwednc |

---AOwednc |

|

D2AOwednc |

Time Dependent Dielectric BreakdownAOwednc |

TDDBAOwednc |

---AOwednc |

|

D3AOwednc |

Hot Carrier InjectionAOwednc |

HCIAOwednc |

---AOwednc |

|

D4AOwednc |

Negative Bias Temperature InstabilityAOwednc |

NBTIAOwednc |

---AOwednc |

|

D5AOwednc |

Stress MigrationAOwednc |

SMAOwednc |

---AOwednc |

|

TEST GROUP E – ELECTRICAL VERIFICATION TESTSAOwednc |

|

#AOwednc |

STRESSAOwednc |

ABVAOwednc |

SAMPLE SIZE / LOTAOwednc |

|

E1AOwednc |

Pre- and Post-Stress Function/ParameterAOwednc |

TESTAOwednc |

AllAOwednc |

|

E2AOwednc |

Electrostatic Discharge Human Body ModelAOwednc |

HBMAOwednc |

See Test MethodAOwednc |

|

E3AOwednc |

Electrostatic Discharge Charged Device ModelAOwednc |

CDMAOwednc |

See Test MethodAOwednc |

|

TEST GROUP E – ELECTRICAL VERIFICATION TESTS (CONTINUED)AOwednc |

|

#AOwednc |

STRESSAOwednc |

ABVAOwednc |

SAMPLE SIZE / LOTAOwednc |

|

E4AOwednc |

Latch-UpAOwednc |

LUAOwednc |

6AOwednc |

|

E5AOwednc |

Electrical DistributionsAOwednc |

EDAOwednc |

30AOwednc |

|

E6AOwednc |

Fault GradingAOwednc |

FGAOwednc |

---AOwednc |

|

E7AOwednc |

CharacterizationAOwednc |

CHARAOwednc |

---AOwednc |

|

E9AOwednc |

Electromagnetic CompatibilityAOwednc |

EMCAOwednc |

1AOwednc |

|

E10AOwednc |

Short Circuit CharacterizationAOwednc |

SCAOwednc |

10AOwednc |

|

E11AOwednc |

Soft Error RateAOwednc |

SERAOwednc |

3AOwednc |

|

E12AOwednc |

Lead (Pb) FreeAOwednc |

LFAOwednc |

See Test MethodAOwednc |

|

TEST GROUP F – DEFECT SCREENING TESTSAOwednc |

|

#AOwednc |

STRESSAOwednc |

ABVAOwednc |

SAMPLE SIZE / LOTAOwednc |

|

F1AOwednc |

Process Average TestingAOwednc |

PATAOwednc |

---AOwednc |

|

F2AOwednc |

Statistical Bin/Yield AnalysisAOwednc |

SBAAOwednc |

---AOwednc |

|

TEST GROUP G – CAVITY PACKAGE INTEGRITY TESTSAOwednc |

|

#AOwednc |

STRESSAOwednc |

ABVAOwednc |

SAMPLE SIZE / LOTAOwednc |

|

G1AOwednc |

Mechanical ShockAOwednc |

MSAOwednc |

15AOwednc |

|

G2AOwednc |

Variable Frequency VibrationAOwednc |

VFVAOwednc |

15AOwednc |

|

G3AOwednc |

Constant AccelerationAOwednc |

CAAOwednc |

15AOwednc |

|

G4AOwednc |

Gross/Fine LeakAOwednc |

GFLAOwednc |

15AOwednc |

|

G5AOwednc |

Package DropAOwednc |

DROPAOwednc |

5AOwednc |

|

G6AOwednc |

Lid TorqueAOwednc |

LTAOwednc |

5AOwednc |

|

G7AOwednc |

Die ShearAOwednc |

DSAOwednc |

5AOwednc |

|

G8AOwednc |

Internal Water VaporAOwednc |

IWVAOwednc |

5AOwednc

满足AEC-Q100仅仅只是车规芯片的第一步,其实要求真正的达到车规芯片的质量,还需要从设计开发流程体系,生产制造体系各个方面来把控,才能真正的满足汽车的质量要求。

|

最前沿的电子设计资讯

最前沿的电子设计资讯